Process Engineering Group

Providing services in this section include:

- Preparation of instructions and method of sampling boreholes and exploratory tunnels based on the saved storage model for completing and monitoring the layout of the arboreal studies.

- Preparation of the procedure and method of preparation and crushing of the samples taken and supervising its performance.

- Preparation of instructions and procedures for conducting pilot-scale arranger experiments to complete and supervise the factory circuit.

- Preparation of instructions and procedures for conducting laboratory-scale ornamental tests to complete and validate previous studies and monitor the implementation of these.

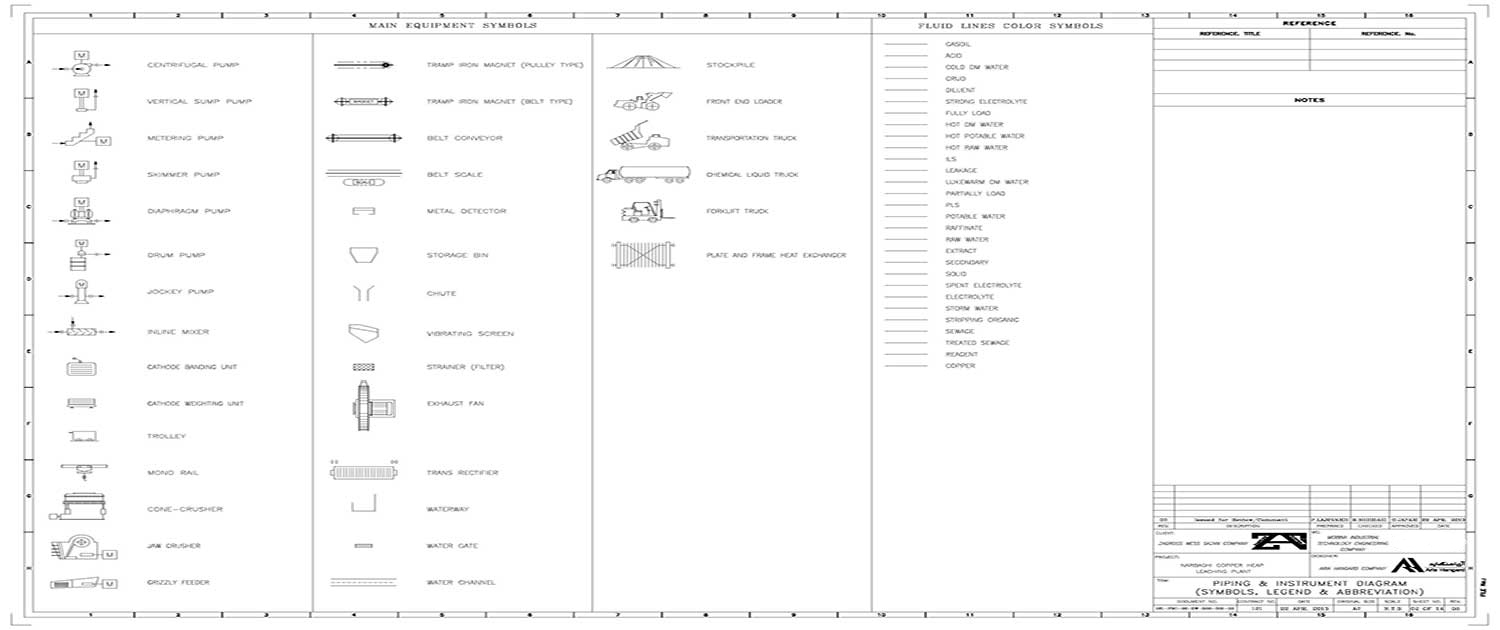

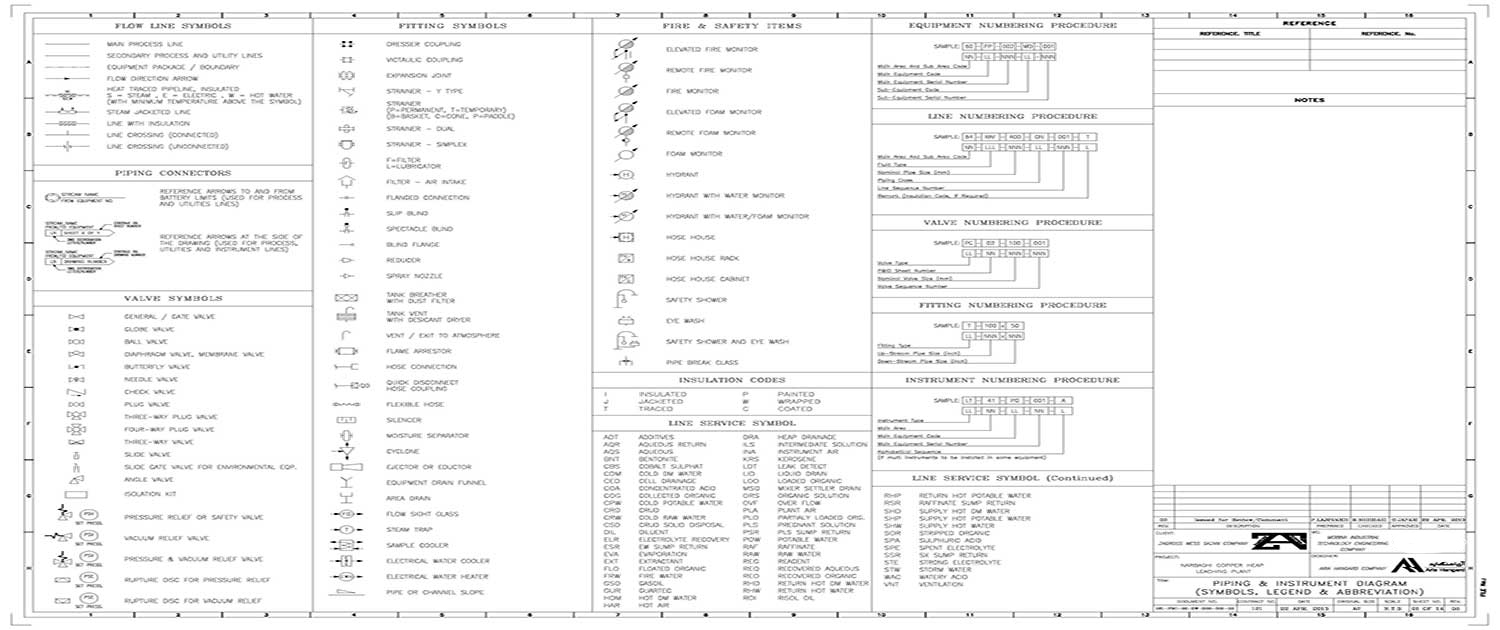

- Preparation and presentation of the blasting plant and determination of the general specifications of the equipment.

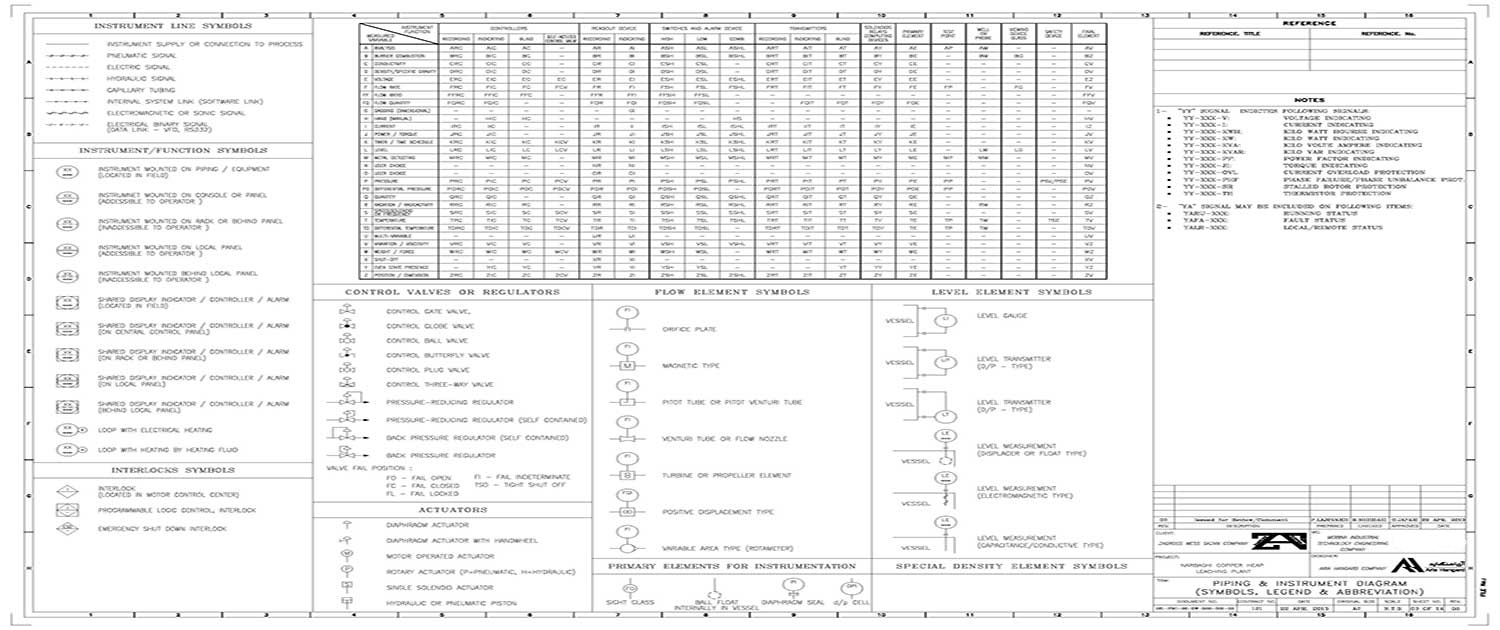

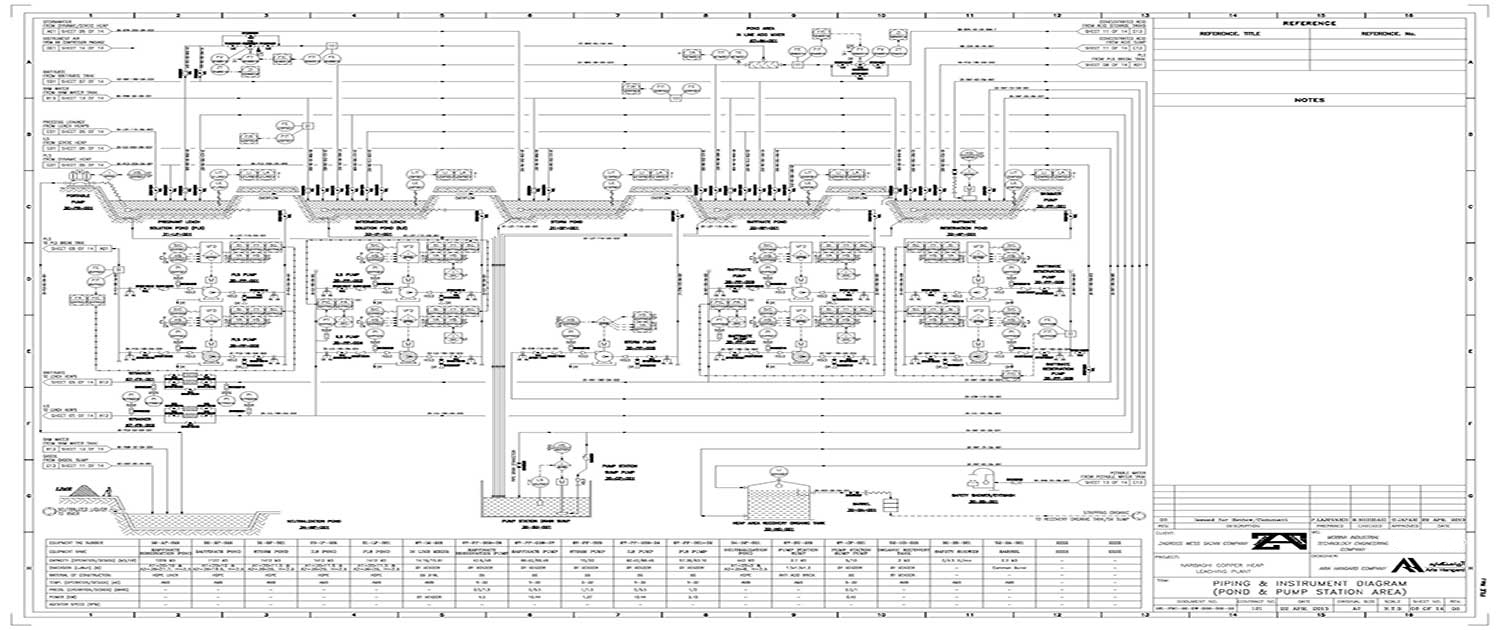

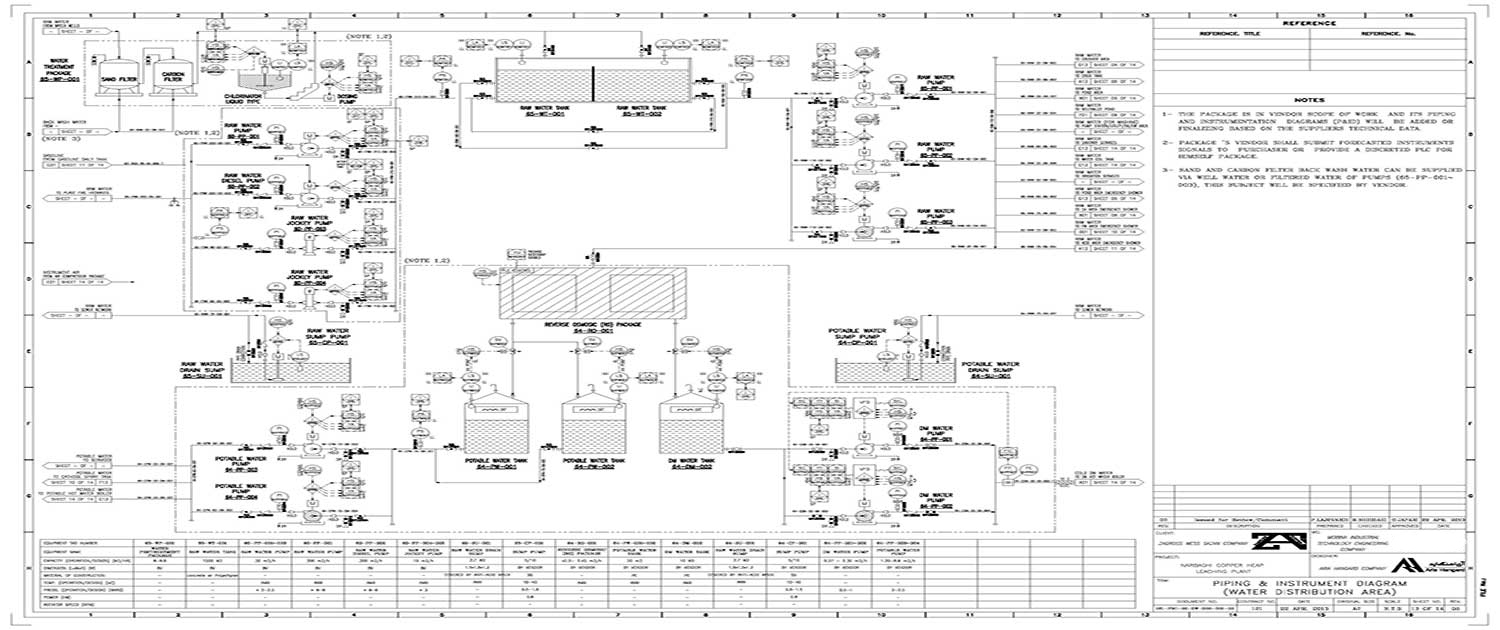

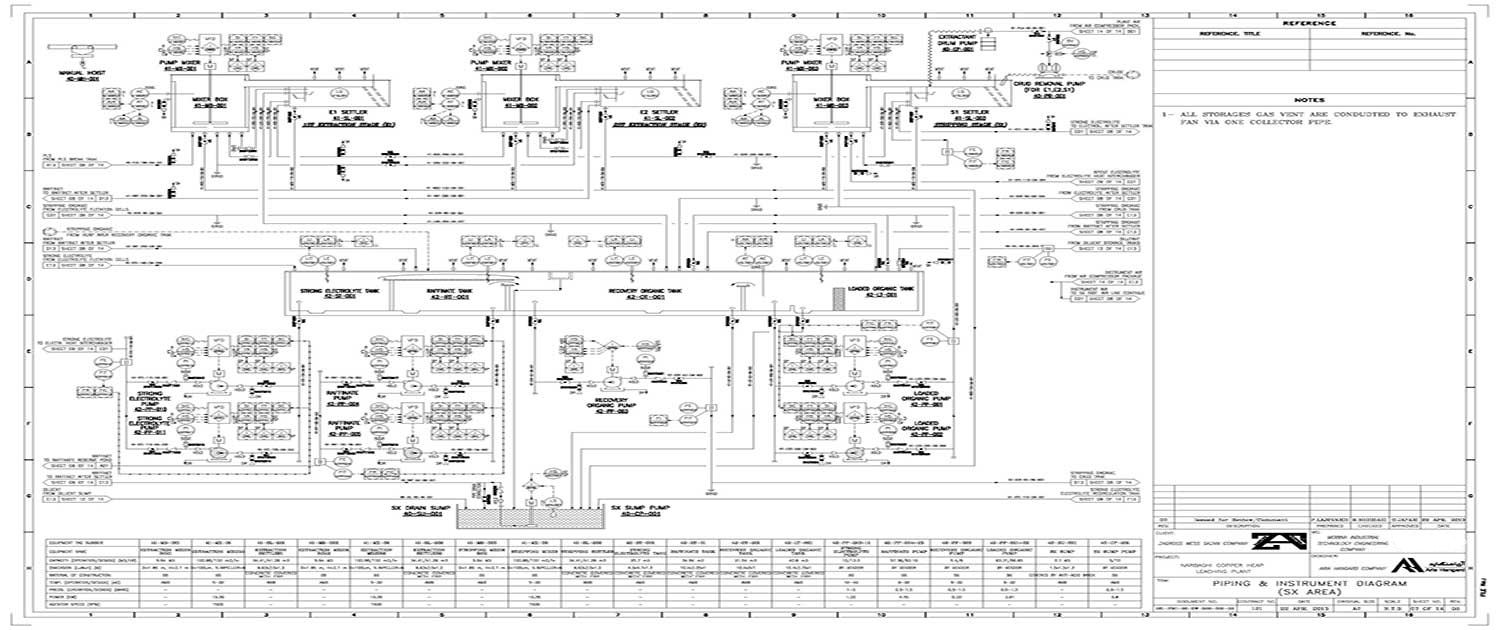

- Provide and deliver the process flow and related utilities.

- Design, modeling and simulating processes.

- Perform mass balance calculations and present the results of Mass Balance Plant.

- Selection of capacity and specification of machinery and equipment in accordance with the objectives of the design process.

- Evaluate the correct changes in feed, fluctuations and out-of-service equipment.

- Optimize and increase plant capacity.

- Determine the amount of consumables and utilities required (water, electricity, fuel, etc.).

- Estimating the requirements of industrial facilities Designing and specifying the general specifications of related equipment.

- Estimated areas for the accumulation and harvesting of raw materials and products.

- An initial review of the plant deployment location and the production of factory layouts and related calculations.

- Mineral environmental studies, tailings dump and sedimentation dam.

- Preparation of technical and engineering reports in the processing sector.

The software used in this group is:

- ASPEN PLUS

- HYSYS

- PRO II

- ASPEN B-JAC

- HTFS

- USIM PAC

- RTD BOTH

- MGOTIC

- BMCS

- MODSIM

- DX ۷